Cranes are essential pieces of equipment in construction and industrial operations. With their powerful lifting capabilities and flexible operation, cranes are widely used around the world in a variety of working environments. Although we often see cranes in everyday life, many people are unfamiliar with their operating principles, classifications, and applications. This article provides a professional, in-depth overview of crane-related knowledge—from how they work to where they’re used.

1. What Is a Crane?

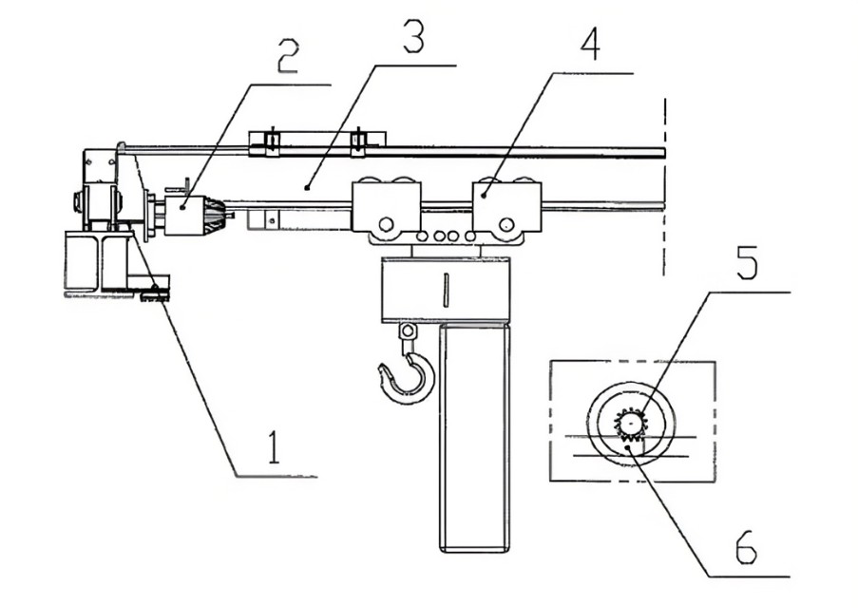

A crane is a mechanical device designed for vertically lifting and horizontally moving heavy loads. It typically consists of a power system, transmission mechanism, working unit, and control system, enabling efficient material handling within a confined area.

Cranes are engineered with various working conditions in mind. Their design focuses on load capacity, stability, and operational flexibility to ensure both safety and efficiency in real-world tasks.

2. How Do Cranes Work?

- Lifting: Electric motors or hydraulic systems power the lifting mechanism to raise or lower the load vertically.

- Slewing (Rotating): The crane’s rotation mechanism moves the boom or entire structure horizontally to reposition the load.

- Luffing (Radius Adjustment): The angle or length of the boom is adjusted to change the working radius and suit various operational ranges.

3. Types of Cranes

- Cranes come in many types, categorized by their structure and application:

- Tower Cranes: Commonly seen at high-rise construction sites, ideal for lifting materials to great heights.

- Crawler Cranes: Equipped with crawler tracks for mobility, suited for rugged terrain and frequent relocation.

- Truck-Mounted Cranes: Installed on trucks for flexible, on-the-go lifting tasks across multiple locations.

- Overhead (Bridge) Cranes: Typically used in factories and warehouses for moving heavy loads over wide horizontal spans.

4. Common Crane Applications

Cranes serve a wide range of industries and scenarios, such as:

- Construction Sites: For transporting materials, installing equipment, and lifting structural components into place.

- Ports and Terminals: Used for rapid loading and unloading of containers, bulk cargo, and heavy goods.

- Factories and Workshops: Integral to production lines for moving materials—overhead cranes are especially common.

- Wind Farms and Power Projects: Large crawler cranes are key to installing wind turbines and high-voltage towers.

5. Key Safety Practices for Crane Operation

Cranes handle large and heavy loads, so improper operation can result in serious accidents. It is essential to follow safety protocols:

- Regular Equipment Inspections: Check wire ropes, hooks, control systems, and other parts to ensure optimal condition.

- Never Exceed Load Limits: Always adhere to the crane’s rated capacity—overloading is a major safety hazard.

- Keep the Work Area Clear: Ensure the ground is free of obstructions and that unauthorized personnel are not in the operating zone.

- Certified Operators Only: All crane operators must receive professional training and hold valid operating licenses.

6. Future Trends in Crane Technology

As technology advances, crane systems continue to evolve. Current trends include:

- Smart Control Systems: Modern cranes are increasingly equipped with remote monitoring and automation features for enhanced precision and efficiency.

- Energy Efficiency and Sustainability: The adoption of eco-friendly motors and energy-saving technologies helps reduce environmental impact.

- Modular Design: Cranes are becoming more adaptable to different work environments through modular components and flexible configurations.

Conclusion

Cranes play a vital role across countless sectors, far beyond traditional construction. By understanding how cranes work, their classifications, applications, and safety guidelines, we gain a deeper appreciation for their importance in modern industry.

We hope this article has helped you develop a more comprehensive understanding of cranes and their value in today’s world.